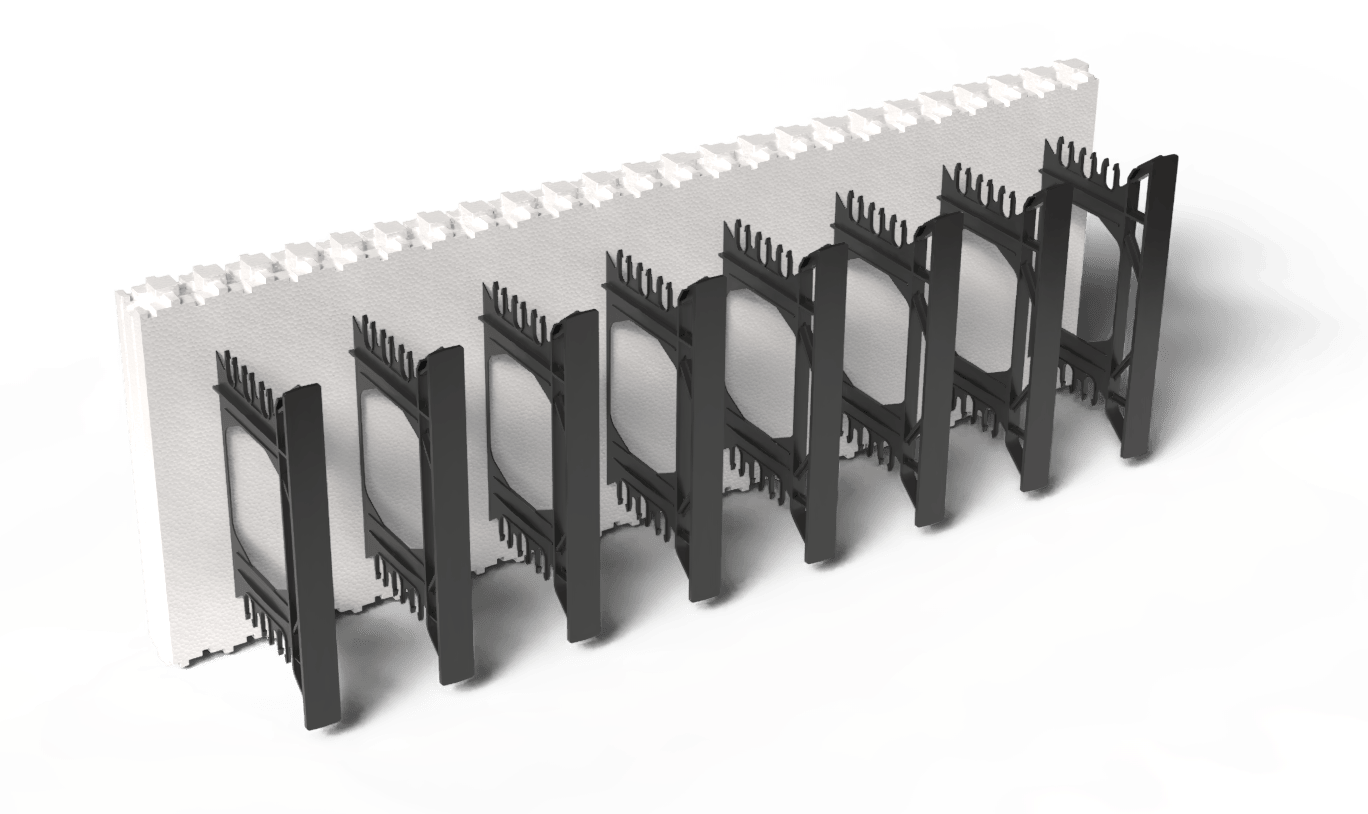

Amvic™ Insulated Concrete Forms (ICF) are a stay-in-place, 5-in-1 concrete forming system incorporating structure, insulation, an air/vapor barrier, and a finish attachment. This cost-effective, resilient, and environmentally friendly construction system is revolutionizing modern construction for a greener tomorrow.

Amvic™ Insulated Concrete Forms (ICF) are a stay-in-place, 5-in-1 concrete forming system incorporating structure, insulation, an air/vapor barrier, and a finish attachment. This cost-effective, resilient, and environmentally friendly construction system is revolutionizing modern construction for a greener tomorrow.

Amvic™ ICF R22 is a cost effective ICF block providing excellent performance and value to any construction project. The combination of patented FormLock™ interlock and reversible block makes for a fast and easy installation, while considerably reducing job site waste. A wide range of available forms and core sizes allows for limitless design possibilities.

| Thermal Resistance | R22 hr.ft2.F/Btu (3.87 m2K/W) |

|---|---|

| EPS Panel Thickness | 2 1/2” (63.5mm) |

| Web Spacing | 6” (152mm) on center |

| Available Core Sizes | 4” x 16” (102mm x 406mm) 6” x 16” (152mm x 406mm) 8” x 16” (203mm x 406mm) 10” x 24” (254mm x 610mm) 12” x 24” (305mm x 610mm) |

| Block Types | Straights 90° corner 45° corner Taper top Brickledge T-block Radius |

Amvic™ ICF R30 is a higher performance ICF block where EPS panel thickness has been increased by 30% making it the highest R-value of any factory assembled block in the industry. The patented FormLock™ interlock has also been improved with the addition of integrated drainage channels. The Amvic™ ICF R30 block is designed to meet the ever-increasing energy efficiency requirements.

| Thermal Resistance | R30 hr.ft2.F/Btu (5.28 m2K/W) |

|---|---|

| EPS Panel Thickness | 3 1/4” (82.5mm) |

| Web Spacing | 8” (203mm) on center |

| Available Core Sizes | 6” x 16” (152mm x 406mm) 8” x 16” (203mm x 406mm) |

| Block Types | Straights 90° corner 45° corner Taper top Brickledge Radius |

Amvic™ One is a single-sided ICF that allows for an uninterrupted foam-to-concrete interface and eliminates the need for foam stripping. Amvic™ One forms are suitable for commercial and specialty applications, including parging-free above-grade exterior walls, elevator shafts, and facilities with restricted high-heat spaces.

Amvic™ One ICF is compatible with all available Amvic™ Standard and Plus block sizes.

| | Standard Block | Plus Block |

| Thermal Resistance* | 4.0 F.ft2.hr/Btu (0.70 m2K/W) |

4.0 F.ft2.hr/Btu (0.70 m2K/W) |

|---|---|---|

| EPS Panel Thickness | 2 1/2” (63.5mm) | 3 1/4” (82.5mm) |

| Web Spacing | 6” (152mm) on center | 8” (203mm) on center |

| Available Core Sizes | 6” (152mm) 8” (203mm) 10” (254mm) 12” (305mm) 14” (356mm) |

8 3/4” (222mm) 10 3/4” (373mm) |

*Measurement per 1” (25mm) of thickness

The Amdeck™ system is an insulated, stay in place concrete form that can be used for virtually any floor or roof construction. It is compatible with any wall type that would normally be used with a typical concrete slab. It is a 4-in-1 system offering structure, insulation, sound attenuation and finished attachment. Amdeck™ is a cost effective, resilient and environmentally friendly construction system helping revolutionize modern construction and change the way we build.

Amdeck™ Eco is designed for low-rise residential applications with longer sections increasing construction speed. The use of dimensional lumber for the joists simplifies the construction by using a commonly available construction material.

Ideal for small buildings and low rise residential.

| Form Heights | 8” (203mm), 10” (254mm), 12” (305mm) |

|---|---|

| Form Length | 8’ (2.4m) |

| Concrete Beam Spacing | 24” (610mm) |

| Joist Type | Dimensional lumber |

| Joist Spacing | 12” (305mm) |

| Shoring Requirements* | Every 4’ (1.2m) |

*Site specific shoring requirements to be approved by an engineering professional.

Amdeck™ Pro is designed for commercial applications with compact modular design allowing the forms to be easily transported and installed even in smaller spaces. The forms have embedded polypropylene webs offering even greater temporary construction load distribution to the metal joists.

Ideal for all construction sectors, residential, commercial and institutional.

| Form Height | 12” (305mm) |

|---|---|

| Form Length | 24” (610mm) |

| Concrete Beam Spacing | 32” (813mm) |

| Joist Type | Lightweight steel C-channel |

| Joist Spacing | 16” (406mm) |

| Shoring Requirements* | Every 8-12’ (2.4-3.6m) |

*Site specific shoring requirements to be approved by an engineering professional.

The AmBuck™ Insulated Block-Out System is a stay-in-place buck formwork designed for creating window and door openings in Insulated Concrete Form (ICF) construction. It replaces traditional wood and vinyl block-outs with a more energy-efficient and durable solution that integrates seamlessly with ICF structures. AmBuck™ provides long-term thermal resistance, prevents thermal bridging, and ensures a faster, more reliable installation process.

A fully insulated buck system that offers stable, long term thermal resistance that surpasses typical wood or vinyl bucks.

AmBuck™ prevents warping, checking, cupping, bowing, rotting, and splitting from occurring, that is seen in most conventional wood-based block-out systems.

| Thermal Resistance | 4.2 F.ft2.hr/Btu per inch (0.74m2K/W per inch) |

|---|---|

| Compressive Strength | 20 psi (138 kPA) |

| Compatibility | Compatible with 6” (152mm) and 8” (203mm) core ICF systems. |

Alleguard offers a range of accessories to increase the efficiency of your Amvic™ ICF projects.

A faster, more efficient way of bracing window and door bucks.

Burmon ICF Buck Brace

Accessories for Amvic™ ICF Brick Ledge and other forms.

Amvic™ ICF Brick Ledge Reinforcer

Amvic™ ICF Brick Ledge Extension

Complete bracing system for quick, accurate and professional ICF installations.

Plumwall ICF Bracing System

Range of waterproofing products for below grade ICF construction.

Platon Foundation Wrap

Soprema Colphene ICF

Soprema Elastocol Stick H2O

Range of parging products for below grade ICF construction.

DuRock Fiberglass Mesh

DuRock B2000

Engineered floor mounting system for ICF construction.

Simpson Strong-Tie ICFVL Ledger Connector System

Become proficient in Amvic™ ICF installation with our comprehensive training programs.

Join the Alleguard family as a qualified installer of Amvic™ ICF systems. Fill out a request form, and qualified installers will receive an installer card through their sales account managers. Installer cards are valid for 3 years and serve as a testament to your expertise in ICF construction.

Anyone can become a qualified Amvic™ ICF installer if they are:

Our robust technical resources library helps support architects & installers building with Alleguard insulation materials.

Alleguard prides itself on delivering sustainable insulation solutions, quality customer service, and providing you with an exceptional total cost of ownership and customer satisfaction.

See why builders all over North America choose Amvic™ ICF for their commercial and residential builds.

Amvic™ ICF systems are an excellent alternative for environmentally friendly and long-lasting buildings. There are several elements that make Amvic™ ICF a preferred choice for sustainable construction.

Whether you need a custom solution for a unique project or have a question, we’re here to help.